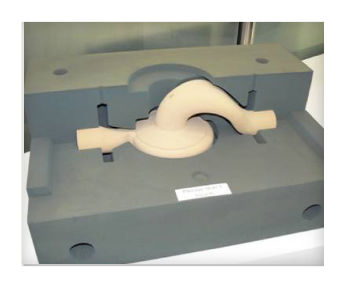

3D Printed Mold

3D Printed Mold Sand Castings

The PumpWorks foundry provides a wide variety of casting services, including:

- 3D digitizing and modeling

- Parts that meet or exceed original OEM in fit, form, and function

- Precise digital modeling vane layouts

- Reverse engineered parts using Hexagon Manufacturing Intelligence

- One-ton piece part capacity in metallurgies from carbon steel through titanium

3D Printed Molds for Foundries

Fast Delivery

- Cores Ship in 2-3 Days

- Full Mold Packages in Less than 5 Days

Engineering Services

- Solidification

- Mold/Core Design

- Metallurgy

Customer Service

- No Set Up Charges and Simple Pricing Structure

- Our Machines Run 24/7

- Secure Packaging and Free Replacement Cores*

Quality Assurance

At PumpWorks, our commitment to ensuring metallurgical and dimensional repeatability prior to melt is paramount. From raw material to final casting products, the PumpWorks quality assurance team monitors every aspect of sand casting and investment casting process. As standard, all castings receive our mandatory 100% visual inspection. Additionally, we employ complete in-house casting inspections which include certified spectroanalysis, physical property testing, non-destructive testing techniques, and live casting X-ray analysis to guarantee metallurgical properties and structural integrity.

Contact us online today to speak with a PumpWorks Castings engineer about how our modern sand casting manufacturing process can serve your needs.